Small Works Update

HYCOVER Rotary distributors are designed to meet a wide range of specific individual applications and for easy installation on site. Wetting rates are selected to meet media type. Distributors are availiable in various configurations, under and over fed; pedestal or drum base support bearing; with or without dosing siphon and either pump or gravity feed, depending on application. Models shown here 'Top Right' is a 9.2mØ self dosing machine on plastic modular media with gravity flow rate of 56m3/hr, under fed. 'Below' shows a 4.7mØ unit with self dosing syphon on stone media with overfeed flow rate of 7m3/hr Both models have support columns, from filter base.

HYCOVER Rotary distributors are designed to meet a wide range of specific individual applications and for easy installation on site. Wetting rates are selected to meet media type. Distributors are availiable in various configurations, under and over fed; pedestal or drum base support bearing; with or without dosing siphon and either pump or gravity feed, depending on application. Models shown here 'Top Right' is a 9.2mØ self dosing machine on plastic modular media with gravity flow rate of 56m3/hr, under fed. 'Below' shows a 4.7mØ unit with self dosing syphon on stone media with overfeed flow rate of 7m3/hr Both models have support columns, from filter base.

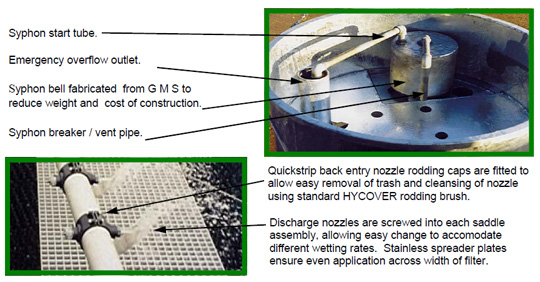

HYCOVER distributors are manufactured from a range of standard components including a galvanized steel central support column with top mounted heavy duty bearing located in the main crosshead. Lubrication is provided via a replacable slow release greaser cartridge. A large capacity galvanised steel bowl is suspended from the crosshead by adjustable support rods. Anti-sway stabilisers are fitted beneath the bowl. Lateral arms are formed from stainless steel with stainless strainer wires connected to the crosshead. Application nozzles are positioned along each arm to ensure even distribution of liquor across the media surface. Nozzles are screwed into each saddle position which also incorporates a back entry 'Quickstrip' nozzle rodding cap and stainless steel spreader plate. Nozzle sizes are easily changed to meet specific flow rates. Washout end caps are provided at the outer end of each arm. HYCOVER Rotary Distributors can be fitted with belt type electric drive and variable rotation speed control.

HYCOVER distributors are manufactured from a range of standard components including a galvanized steel central support column with top mounted heavy duty bearing located in the main crosshead. Lubrication is provided via a replacable slow release greaser cartridge. A large capacity galvanised steel bowl is suspended from the crosshead by adjustable support rods. Anti-sway stabilisers are fitted beneath the bowl. Lateral arms are formed from stainless steel with stainless strainer wires connected to the crosshead. Application nozzles are positioned along each arm to ensure even distribution of liquor across the media surface. Nozzles are screwed into each saddle position which also incorporates a back entry 'Quickstrip' nozzle rodding cap and stainless steel spreader plate. Nozzle sizes are easily changed to meet specific flow rates. Washout end caps are provided at the outer end of each arm. HYCOVER Rotary Distributors can be fitted with belt type electric drive and variable rotation speed control.